Vision Inspection

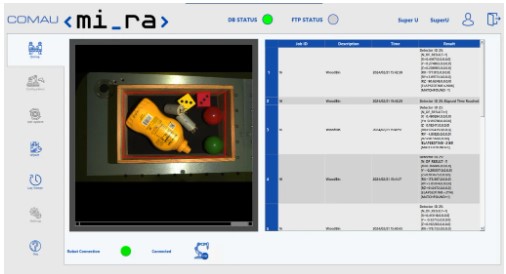

COMAU MI.RA/OnePicker: Intelligent Vision-Assisted Picking

Designed to autonomously pick miscellaneous objects from the same bin without relying on CAD-based assistance (vision-assisted picking) or prior information about their size, shape, color or characteristics, MI.RA/OnePicker is the smart way to increase productivity, worker safety and overall efficiency.

MI.RA/OnePicker - Comau's standard AI-based solution to pick generic objects.

Designed to automate the task of emptying bins full of heterogenous objects, it reduces the need for manual and repetitive operations while increasing productivity and cost efficiency. The powerful State-of-the-Art vision system detects and localizes random displaced objects inside the bin and chooses the best way to empty the bin. In addition, integrated collision-avoidance and safety routines are put in place to avoid dangerous situation and errors in the production process. And because MI.RA/OnePicker ensures unparalleled precision and productivity, it reduces the need for manual and repetitive operations while saving time and costs.

Vision System for 3D Robot Guidance

| • Advanced path planning • User-friendly interface • Mutiple cameras support • Scalable • TCP/IP Communications |

• No CAD needed • Manage multiple objects inside the same bin • Works with vacuum-based grippers |

Applications include: Kitting, Sorting, and E-commerce

View more Automated Vision-Based Solutions - Comau supports clients in the development of smart and flexible collaborative and vision-based technologies backed on advanced robotics, addressing the most complex challenges and production requirements.

|

|

|

To learn more about Comau's MI.RA Vision-based solutions give your local Barry Sales Engineering rep a call at 636.326.1211!

![]()

Leuze - LCAM 408i Industrial IP Camera

Looking Around the Corner - Offering insights into areas which are not accessible by plant operators.

The LCAM 408i camera provides live stream 5Mpixel color video of your machine processing. The rugged IP65/67 metal housing stands up to the worst environments. An anodized version with front window compressed air fitting means working in wet environments is not an issue. Wish you could see your part being processed or provide visual feedback for setup? Now you can!

This robust camera delivers live streams at high image quality due to its gigabit ethernet interface and is easily integrated into the machine or system controller via M12 connections.

| Download Product Brochure |

Leuze - LSIS 400i Series

The Smart Camera of the Next Generation

The Leuze new generation of smart cameras of the LSIS 400i series is literally a "highlight" in our range of products. Thanks to its extreme light-intensive object illumination the camera can illuminate its image field very homogeneously and therefore also master demanding detection tasks without problem.

The motor-driven focus adjustment and the easy operation via webConfig tool make the handling of the system so easy nobody is left in the dark during the operation.

The smart cameras score points compared to more complex systems in particular when it's about fast and low cost integration. The flexible and high-performance systems of the LSIS 400i series are therefore the right choice for many automation applications.

Advantages at a Glance

Homogeneous illumination of the entire image field for considerably better results than with conventional LED illumination

Homogeneous illumination of the entire image field for considerably better results than with conventional LED illumination- The easy configuration via the integrated webConfig tool facilitates and simplifies application setup

- Easy and reliable object detection and inspection through high-performance BLOB analysis

- Integrated connectivity with an RS 232 interface and 8 digital, freely configurable inputs and outputs as well as Ethernet for configuration

- Easy start-up and connection with M12 connection technology and intelligent fastening concept

- Suitable for industrial use: metal housing with glass window and protection rating IP 65

- Flexibility through motor-driven focus adjustment and storage of the lot-specific camera distance in the test program. As a result, no manual focusing is necessary on the device

- Easy diagnostics by means of bilingual display with buttons and LED status displays

- The wide range of accessories simplifies installation, wiring and fastening

Baumer - CMOS Cameras with VisualApplets technology and GigE Vision®

Intelligently Solving Image Preprocessing

Baumer's LX models with VisualApplets technology are a new class of cameras at Baumer for easy, application-specific image preprocessing. This allows for increased throughput, simplified system design or lower system costs.

Since image preprocessing is carried out  directly in the camera's FPGA, real-time application behavior is achieved. At the same time, the volume of data to be transmitted and processed can be reduced so that the PC-based image processing system does not have to perform algorithms requiring considerable processor power.

directly in the camera's FPGA, real-time application behavior is achieved. At the same time, the volume of data to be transmitted and processed can be reduced so that the PC-based image processing system does not have to perform algorithms requiring considerable processor power.

With VisualApplets, the graphical development environment for FPGA programming from Silicon Software, even complex algorithms can be implemented quickly and easily. It allows the user to adapt the camera's range of functions flexibly to the application, and enables efficient and economic image data processing at very high resolution and speed.

3D cameras for high-performance laser triangulation

The LX VisualApplets 3D cameras feature a particularly developed and pre-installed applet for laser triangulation. In favor of this, the laser line focus is located directly in the camera with subpixel accuracy, so transmission will only contain the profile data which will significantly reduce the amount of data. With up to 12-megapixel resolution, up to 4K line width as well as profile rates of more than 2.5 kHz at 128 lines they identify even the slightest deviations reliably at high processing speed.