Robotics

COMAU S-Family: A New Generation of Small Robots

High-speed, energy efficient robots, with payloads of 13 kg and up to 18 kg, that are specifically designed for arc welding and handling applications where accuracy, repeatability and speed are non-negotiable. Application Industries include Foundry, Food & Beverage, Plastics, Chemical Products, Metal, Battery Manufacturing, as well as Automotive.

Features

- Hollow Wrist to facilitate cable routing

- IP65 and IP68 (Wrist) classification: High protection against dust and water

- Hygenic Wrist Design to avoid dust accumulation

- UL94-V0

- Energy Certificate (Fraunhofer IWU Institute)

- Slim and Curved Arm: to minimize interference

- Small Footprint and Low Weight

- Special Features: Fully integrated dressings (optional)

Benefits

- The first robot in the world with fully integrated dressing and panel connectors

on the robot base

on the robot base - Hollow Wrist caters to Arc Welding applications and Hygienic environments

- Best in class protection: IP68 (Wrist)

- Easy to install, integrate, program and use

- Small footprint (33x33cm)

- High repeatability and accuracy

To learn more about Comau's New S-Family of small robots, give your local Barry Sales Engineering rep a call at 636.326.1211!

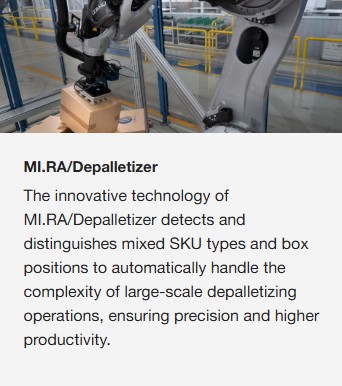

COMAU MI.RA/OnePicker

Intelligent Vision-Assisted Picking

Designed to autonomously pick miscellaneous objects from the same bin without relying on CAD-based assistance (vision-assisted picking) or prior information about their size, shape, color or characteristics, MI.RA/OnePicker is the smart way to increase productivity, worker safety and overall efficiency.

relying on CAD-based assistance (vision-assisted picking) or prior information about their size, shape, color or characteristics, MI.RA/OnePicker is the smart way to increase productivity, worker safety and overall efficiency.

MI.RA/OnePicker - Comau's standard AI-based solution to pick generic objects. Designed to automate the task of emptying bins full of heterogenous objects, it reduces the need for manual and repetitive operations while increasing productivity and cost efficiency. The powerful State-of-the-Art vision system detects and localizes random displaced objects inside the bin and chooses the best way to empty the bin. In addition, integrated collision-avoidance and safety routines are put in place to avoid dangerous situation and errors in the production process. And because MI.RA/OnePicker ensures unparalleled precision and productivity, it reduces the need for manual and repetitive operations while saving time and costs.

Vision System for 3D Robot Guidance

| • Advanced path planning • User-friendly interface • Mutiple cameras support • Scalable • TCP/IP Communications |

• No CAD needed• Manage multiple objects inside the same bin • Works with vacuum-based grippers |

Applications include: Kitting, Sorting, and E-commerce

View more Automated Vision-Based Solutions - Comau supports clients in the development of smart and flexible collaborative and vision-based technologies backed on advanced robotics, addressing the most complex challenges and production requirements.

|

|

|

To learn more about Comau's MI.RA Vision-based solutions give your local Barry Sales Engineering rep a call at 636.326.1211!

COMAU Racer-5-0.80 COBOT

A New Paradigm in General Industry Robotics

Comau Racer5 COBOT is the only collaborative robot

that can automatically switch from industrial robot speed to collaborative speed when a human operator enters in its working area.

It combines flexibility and collaborative safety features with high-performance repeatability and accuracy and allows reducing cycle times while ensuring better productive throughput.

Features

- 5 Kg payload

- 0.809 m reach

- 0.03 mm repeatability

- Collaborative/non-collaborative speed switch

- Up to 500 mm/s cartesian speed in collaborative mode

- Up to 6 m/s cartesian speed in non-collaborative mode

- Safe Collision Detection function – PL d CAT. 3 certified by TÜV Süd

Benefits

- High repeatability and accuracy

- Racer-5 industrial robot speed when no human operator nearby for an increased productivity

- Electrical and air connections near the wrist avoiding external harness

- Immediate awareness of cobot status due to LED stripe

- Long life cycle thanks to mechanical robustness

- Efficiency and flexibility of the cycle

- Reduction of spaces for automation

- Simplified process inspection and quality control

Technical Specifications for the Racer-5-0.80 COBOT

To learn more about the RACER5-0.80 COBOT & the full line of robots, give your local Barry Sales Engineering rep a call at 636.326.1211!

-View the Comau Robotics Compact Catalogue-

Star Automation uses industry leading innovation to develop the best injection molding robots such as automatic unloaders and pallet changers for the IMM plastics industry. Their servo motor driven robots, sprue pickers, are the best solution for increasing the efficiency and profitability of your IMM plastics operation.

|

Servo Robots - Star Automation offers a variety of different size servo motor driven robots with many available options and features. |

|

Sprue Pickers - Star Automation’s swing type sprue picker XQ-V Series consists of a simple and compact design, realized by eliminating unnecessary wirings and piping. It includes an E-stop switch for safe operation located on the easy-to-use operation pendant. The change of release side is easier than ever and has a mold change memory that can operate on up to 15 different molds. |

Perimeter Guards

Protecting a machine or small area is easy, protecting a larger area can be too. Perimeter guards, or safety fences, are barriers used to keep employees clear of an area for safety, security, privacy, or to simply keep a work area looking clean and organized. This is great for applications including robot cells or when a guarding system cannot be attached directly to the machine.

We understand people have variable, scalable perimeter guard needs. Choose from a selection of materials to make your solution as strong or adaptable as you want.

- T-slotted aluminum

- Electronic safety devices

- Wire mesh

- Polycarbonate

- A mixture of multiple product lines for a custom safety guard

|

|

Need a quote? We can help! Give your local Barry Sales Representative a call at 636.326.1211.

![]()